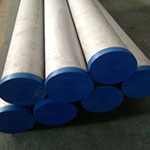

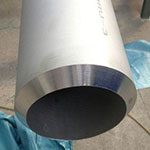

ASTM B729 UNS N08020 Seamless Pipe & Carpenter 20 Tubing supplier in Mumbai, India

Pipes available in the market are made up of various materials such as alloys and metals. One such pipe is the Alloy 20 Pipe that is made up of an austenitic steel material Alloy 20 Pipe manufacturers stabilize these pipes by adding niobium to the alloy. This helps in resisting intergranular corrosion. It offers good resistance to phosphoric acid, sulfuric acid, nitric acid, and aqueous salt solution. Alloy 20 Pipes are the best solution for applications wherein chloride stress corrosion cracking is an issue. However one needs to be cautious with Alloy 20 Seamless Pipe in chloride ion containing environment as it increases the corrosion rate rapidly.

Alloy 20 Welded Pipe can be formed either by hot or cold working. Hot forging material needs to be heated within the temperature range of 2100 degrees F to 2250 degrees F. Post which the Alloy 20 Pipe needs to be quenched with water. A negative effect on the stabilization of the Incoloy Alloy 20 Pipe can be obtained by heating it at a temperature below 2100 degrees F. It is also important to relieve the stress of the said pipe so that it can perform easily. Carpenter 20 Pipeis widely used in chemical processing and petrochemical refining, food processing, and pharmaceutical industries.

Carpenter Alloy 20cb3 Pipe can be used in applications where the temperature is limited to 1000 degrees F. Moreover, UNS N08020 Pipe is also used in storage tanks, mixing tanks, pumps and valves, agitators, fasteners, and fittings. Alloy 20 Pipe suppliers are able to supply these pipes at a lower cost in India due to the low cost of labor and raw material. They are used in plastic as well as power generation industries. B729 Pipe produced by us is passed through various tests that enable us to ensure the properties inherited by them.