Integral Finned Tubes

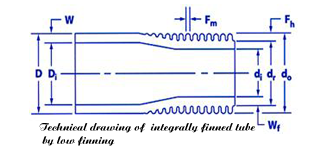

Integrally finned tubes by low finning / Integral fin tube: type low fin:

Integral low fin tube for use in situations where extended surface is required, but lack of space or heat exchanger type dictates otherwise.

Available materials are stainless steel (304L, 316L, 321(H), 304H, 310, …), duplex, copper alloys, nickel alloys, hastelloy and titanium

Integral Low Fin Tube has the advantage that it can improve the thermal performance of a heat exchanger without the necessity for changing shell size, flow arrangement or the repositioning of piping.

Finned heat exchanger bundle Finned heat exchanger bundle |

The external surface of the tube is increased by the formation of ''low fins'' by direct extrusion from the material of the base tube.

Size range / Dimensions:

- Tube size: 12,7mm, 15,88mm, 19,05mm and 25,4mm

- Fins per inch: 16, 19, 26, 28, 30, 32, 36, 40 and 43 fins/inch dependant on material

Quality test capabilities :

- Non-destructive eddy current examination

- Air under water testing

- Hydrostatic testing (with fluorescent dye)

- Fin profile examination at 50x magnification

- Dimensional & ring gage checks

Applications :

- Refrigeration, air conditioning, condenser, heat exchanger, boiler

| Norms: |

| ASME pressure vessel code Sec.8, UG-8 and Div. 1 appendix 23 |

| ASTM B891 |

Standard Specification for Seamless and Welded Titanium and Titanium Alloy Condenser and HeatExchanger Tubes With Integral Fins |

| ASTM A1012 |

Standard Specification for Seamless and Welded Ferritic, Austenitic and Duplex Alloy Steel Condenser And Heat Exchanger Tubes with Integral Fins |

| ASTM B924 |

Standard Specification for Seamless and Welded Nickel Alloy Condenser and Heat Exchanger Tubes With Integral Fins

|

| ASTM A498 |

Standard Specification for Seamless and Welded Carbon, Ferritic and Austenitic Alloy Steel Heat Exchanger Tubes with Integral Fins |

| ASTM B359 |

Standard Specification for Copper and Copper-Alloy Seamless Condenser and Heat Exchanger Tubes With Integral Fins

|

In specifying finned tubes you should advise:

Number of finned tubes required Number of finned tubes required- Outside diameter of tube

- Tube thickness or thickness required under root of fin

- Length of finned tube

- Number of fins per inch

- Unfinned ends

- Skipped portions and dimensions from one end

- Material of tube

In specifying U-tubes you should advise:

-Tube diameter, thickness and material

-Straight leg length

-Centre line radius (or diameter) and number off per row

-Whether post bend heat treatment is required

-Whether hydraulic testing is required

|